The cost of FDM 3D printing can vary widely depending on a variety of factors, including the complexity of the print, the quality of the print, the materials used, and the software and hardware required.

In this post, we will explore the costs associated with FDM 3D printing for both hobbyists and professionals.

Hardware Costs

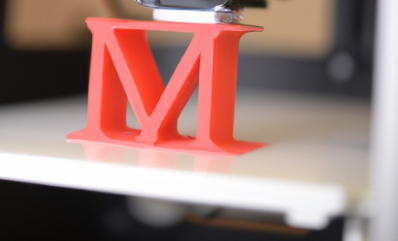

The cost of the 3D printer itself is one of the most significant factors in the overall cost of FDM 3D printing.

The price of 3D printers can range from a few hundred dollars for entry-level models to tens of thousands of dollars for professional-grade models.

Hobbyists may be able to get by with a lower-end model, while professionals may require more expensive models with larger build volumes and more advanced features.

It’s important to consider the long-term cost of ownership when purchasing a 3D printer, as factors such as maintenance, repair, and replacement parts can add up over time.

Material Costs

The cost of the material used in FDM 3D printing can also vary widely depending on the type of filament used.

PLA filament, a popular and widely used thermoplastic, can cost as little as $20 per kilogram. However, more advanced filaments such as ABS, Nylon, or PETG can cost upwards of $50 per kilogram.

Additionally, specialty filaments such as flexible or glow-in-the-dark filaments can cost even more.

It’s important to consider the cost of material when selecting a filament for a project, as well as any additional costs such as shipping or storage.

To better understand the real-world costs associated with FDM 3D printing, let’s look at a few examples of different projects and their associated costs:

1. Hobbyist Project – A small figurine

A hobbyist may want to print a small figurine, measuring around 10 cm tall.

They may use a low-cost PLA filament and an entry-level 3D printer. The cost of the filament would be around $20 per kilogram, and assuming the figurine used around 50 grams of filament, the material cost would be around $1.

The cost of the 3D printer could be around $300. Assuming the hobbyist spends around 2 hours designing, slicing, and printing the figurine, and doesn’t factor in any labour costs, the total cost would be around $301 and $1 per figurine.

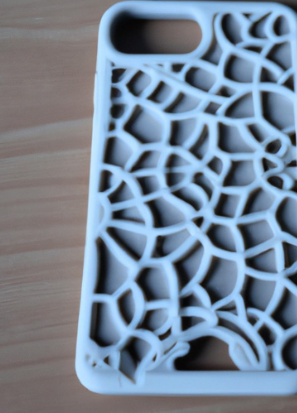

Small Business Project – Production run of 50 phone cases

A small business may want to produce 50 phone cases for a new product line.

You can use a rubber filament and a mid-range 3D printer with a moderate build volume.

The cost of the filament would be around $30 per kilogram, and assuming each case used around 50 grams of filament, the material cost per case would be around $3.

The cost of the 3D printer could be around $500.

Assuming the business spends around 5 hours designing, slicing and 20 hours. printing, and finishing the phone cases, and does factor in labour costs, the total cost per case would be around $5-8.

With a production run of 50 cases, the total cost would be around $750.

Want some ways to make money with 3D printing?

Here is a blog on 4 different ways of making money on 3D printing.